Unique Properties for High-Performance

Industrial Applications

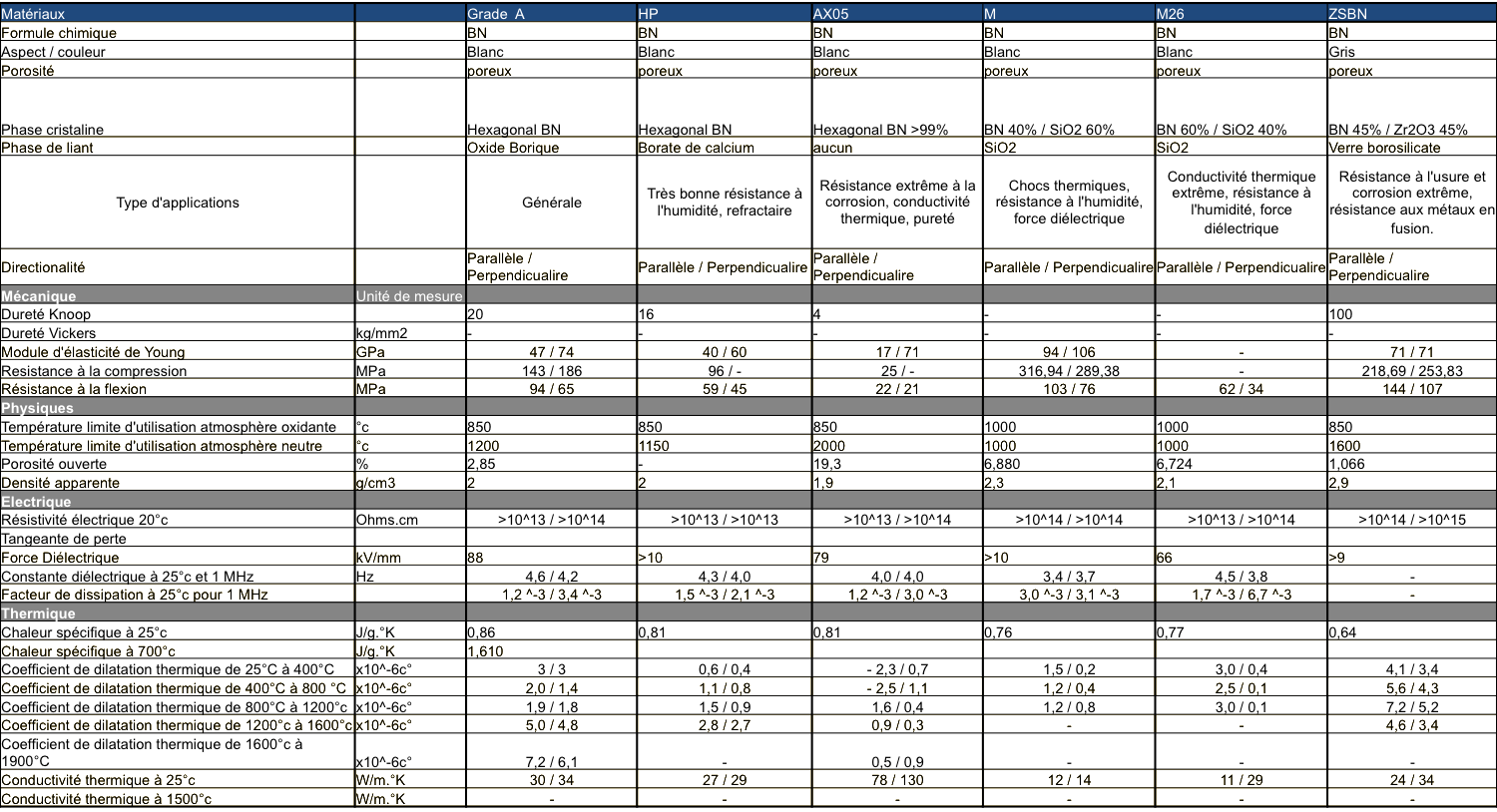

Combat®, a hot-pressed hexagonal Boron Nitride, exhibits a unique combination of chemical, electrical, mechanical and thermal properties, making it suitable for a wide range of high-performance industrial applications.

Combat Boron Nitride’s characteristics depend on the type and amount of binder, overall composition and the type of bond between layers. Backed with industry leading international technical support from Saint-Gobain, Combat provides a full spectrum of solutions in machinable blanks as well as custom finished shapes.

COMBAT AX05 – Does not use any binder and is self bonded, offering the highest purity for high temperature applications. Non-wet by almost all molten metals, AX05 is recommended for applications such as extreme high-temperature insulators and crucibles for high-purity processing.

COMBAT M AND M26 – Combine the moisture resistance of silica with unique properties of boron nitride. Differentiated by the amount of SiO2, Combat M offers unparalleled resistance to thermal shock while Combat M26 offers higher thermal conductivity. M and M26 are ideal for applications requiring extreme and exacting dielectric properties.

COMBAT ZSBN – Combines the non-wetting properties of boron nitride with extreme refractory and wear resistance of zirconia. ZSBN is widely used in a variety of molten metal contact applications.

COMBAT A – Uses boron oxide as a binder to create a hard, dense yet easily machinable product best used in inert and dry environments. It is ideal for general purpose high-performance applications.

COMBAT HP – Leverages Boron Nitride’s outstanding thermal shock resistance with Calcium Borate glass’s moisture resistance. HP is ideal for light metal processing application such as aluminum, magnesium and zinc, particularly electrical insulation applications for up to 1000°C.