BORON CARBIDE

BORON CARBIDE (B4C)

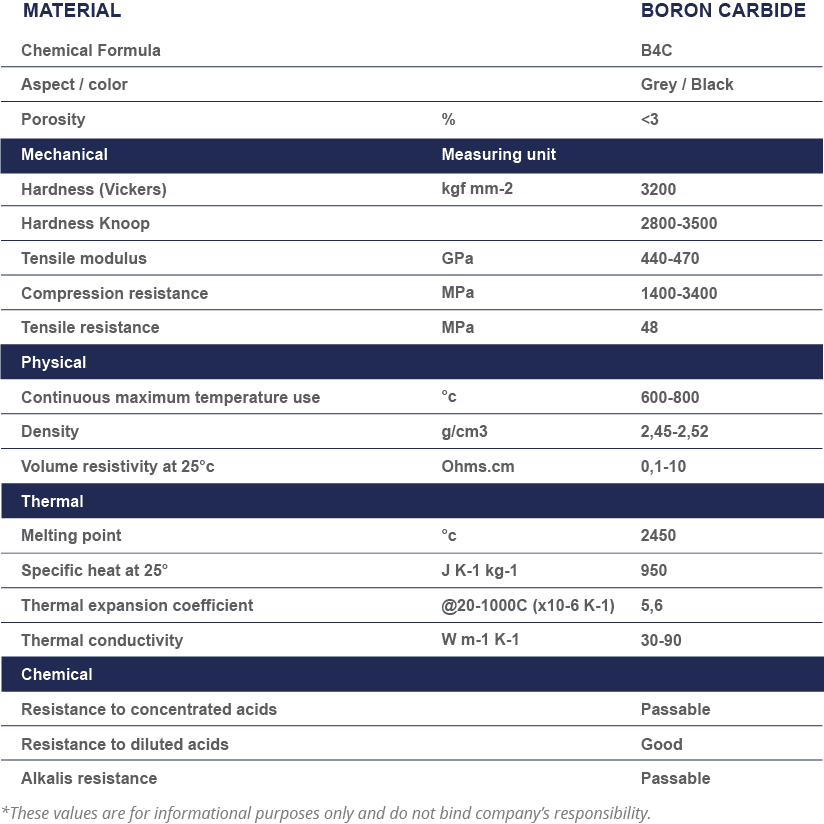

Basic properties

Applications

Boron carbide (chemical formula approximately B4C) is an extremely hard boron–carbon ceramic material used in tank armor, bulletproof vests, and numerous industrial applications. With a Mohs hardness of about 9.497, it is one of the hardest materials known, behind cubic boron nitride and diamond.

B4C can be mirror polished and has a very good resistance to acids. It is refractory and chemically inert. However, it is less resistant to oxidation than Silicon Carbide.

Boron Carbide Production methods:

Hot pressing and Hot isostatic pressing are good means for producing such a ceramic.

B4C is fully dense and has a pure single phase shape.

Hot pressing has the inconvenient of limiting the available sizes and shapes that could be produced.

B4C is machined with diamond tools.