ALUMINA C799

ALUMINA C799

ALUMINA C799

Basic properties

Very hard Abrasion resistant Can be milled with great precision Can be polished Stable at high temperatures No open porosity Excellent electrical properties Chemically inert High corrosion resistant.

Applications

Mechanical components Pistons, pump stages Mechanical seals Sealing bushes Faucet keys and seats Electrical insulator Pyrometry Laboratory items, crucibles Vacuum items Welding nozzles.

Realisations

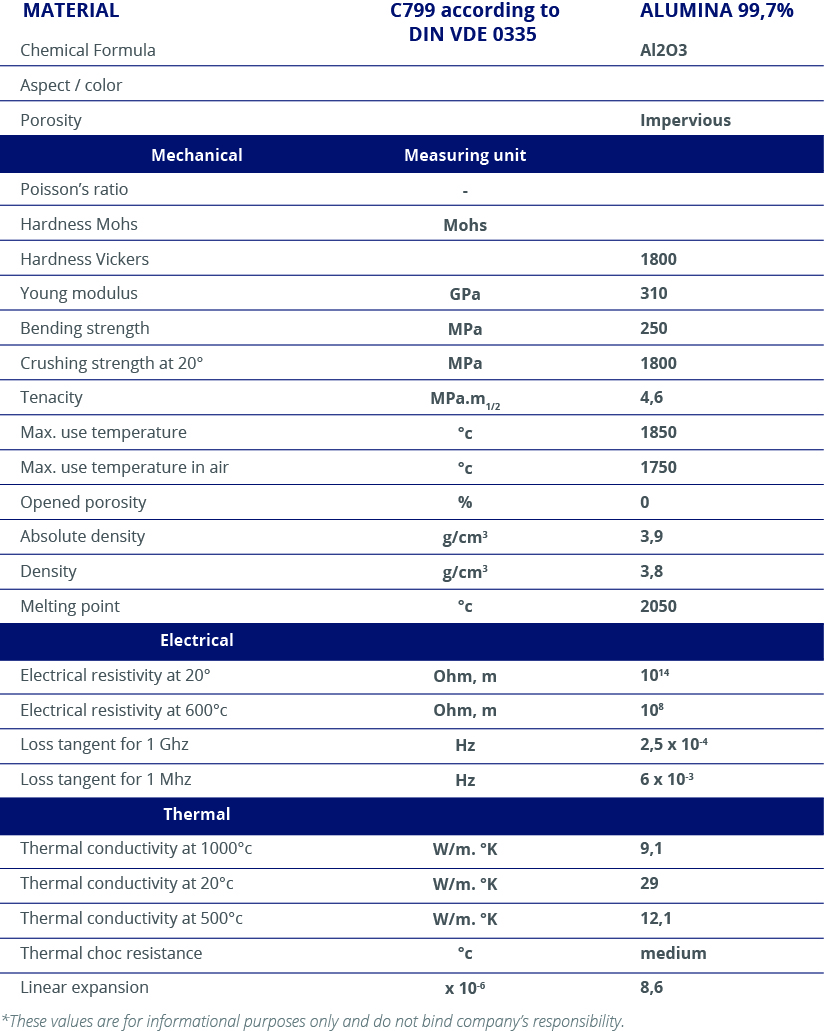

Chemical composition: Aluminium Oxide 99,7% / Silica: 0,05% / Magnesia 0,03 % Sodium Oxide 0,15% / Iron oxide 0,02% / Calcium Oxide 0,03% / Titanium Oxide <0,01 / Boron Oxide <0,02%